Flower boxes in cor-ten steel: holidays at Conero Azzurro set in design

3 June 2016

Corten cladding: Pagliarini Viaggi has a new brown look

3 February 2017Corten steel: here advantages and applications of a material that for aesthetic features and capabilities is becoming increasingly appreciated and used.

Corten steel: the elegance of the “rust”

In 1933 the United States Steel Corporation (USS) patents for the first time the Corten steel, today one of the most important materials among the types of low-alloy content (originally 0.2-0.5% copper, 0.5-1.5% chromium and 0.1-0.2% phosphorus) and high mechanical strength. The name “Cor-Ten” comes, in fact, by two English words that define the main features: “Cor-rosion resistance” and “Ten-sile strength”, ie high resistance to corrosion and mechanical resistance.

The real work research on this material, however, is developed from the ’60s: the renowned architect Eero Saarinen employed for the first time the corten in an architectural context, with the creation of the John Deere World Headquarters in Illinois in 1964.

Thus began the history of corten metal that today, for its ability to combine functionality and aesthetics, is widely used in many industries, from construction to road network up to the decorative contexts.

The corten steel, or the “living metal”

The great success of corten steel is due certainly to its “self-protection” capabilities. This metal, in fact, during the oxidation process, it covers itself of a coating composed of:

- an outer porous layer;

- an inner layer, very thin, rich in copper, chromium and phosphorus that is amorphous and waterproof.

This coating, in normal environmental conditions, will form in about 18-36 months and its color varies from an initial orange to a brownish-reddish color. It is what is commonly called “rust” but that for the Corten right for its color characteristics (joined to the functional ones), is protective and lends itself to the most various design solutions. Not only that if this coating is scratched, the oxidation process starts to build a new protection. This is why the Corten is a material which “lives and protects itself”.

In order to form the patina, properly, there are some key factors including:

- alternating cycles dry / wet;

- contact with the atmosphere;

- action of sunlight;

- absence of permanent stagnation with water.

The advantages deriving from this unique feature are countless. The corten metal, in fact:

- it has a lower cost compared to normal steels because, in the same mechanical resistance, it is possible to achieve considerable reduction in thickness and thus also in weight;

- it has excellent resistance to atmospheric corrosion that allows you to use the corten metal whether or not “naked.” The passage of time does not damage the material, but on the contrary gives that aspect of “lived” conquering architects and designers;

- it may be subjected to different types of machining (forging, bending, drawing, machining, cutting, welding) and this makes it suitable for the most varied design requirements.

Cor-Ten A, B, C: composition and differences

The Corten steel is divided into three types which differ in their chemical composition and their thickness and consequently also for the type of application.

Corten steel A

This type of Corten is also called “phosphor” and has the following “structural” features:

|

Features |

Corrosion resistance (compared to common carbon steels) |

Available thickness |

Applications |

| Corrosion stops after having caused a decrease of approximately 0.05 mm thick | 8 times higher |

Up to 12.5 mm |

architectural |

Corten steel B

It is the so-called Corten “vanadium”:

|

Features |

Corrosion resistance (compared to common carbon steels) |

Available thickness |

Applications |

| The high mechanical characteristics of the material are retained even in large thicknesses | 4 times higher |

Up to 100 mm |

Buildings subjected to severe stress |

Corten steel C

|

Features |

Corrosion resistance (compared to common carbon steels) |

Available thickness |

Applications |

| Recently introduced on the market, it has a significantly higher mechanical strength than the steels of type A and B. | 4 times higher |

Up to 25.5 mm (with the exception of the sections in which thickness is 19 mm max) |

Buildings subjected to severe stress

|

The false corten: how to learn to recognize it

In recent years the diffusion of Corten steel has considerably increased and this has led to the introduction of many imitations of this material on the market. Generally, the processes by which one tries to reproduce the corten effect may be divided into three types:

- metallization: this involves the application of a thin layer of Corten steel on an original carbon steel surface. In this case the aesthetic appearance is very similar to that of true Corten, but being the traditional steel according any surface scratching causes the oxidation of the underlying metal without restarting the creation of the protective coating process;

- painting: there are paintings reproducing the rust effect. In this case, however, the effect of “lived” is standardized: it fails the living material component which has made the fortune of corten;

- simple oxidation: iron rust too has the same look of corten. The difference is that in this case, with time tends to be removed from the surface, leaving only the characteristic deterioration of the iron.

Corten steel: Applications

The contexts in which the corten can be applied are many:

- Design forms that integrate architecture and landscape: in this case the Corten is leading a creative encounter between art, history and architecture. The aim is to make tangible the interconnection relationship between the architectural elements and the environmental context in which they arise.

An interesting example in this regard, is the work of Cuadra in the project “Brisighella Nuova 2.0 – Comunità Ospitale “: the aim is to create an urban space that can improve the lives of citizens and to enhance, in smart perspective, all the excellence of the small town in the province of Ravenna.

The metal corten flower pot holders signed Cuadra, in fact, have been placed in Piazza Marconi, the main square of the Brisighella village, and integrate with the surrounding space and tying favoring the balance between aesthetics, functionality and architecture. Every centimeter of the square thus acquires its value and becomes green “living.”

To discover the project see “Cuadra’s corten steel planters in Brisighella: a green space to be thoroughly enjoyed”

- Surface use: corten steel is very well suited to the realizations of particular indoor/outdoor which are able to impart an elegant and welcoming appearance.

- Outdoor area – urban design: the need in this case is to characterize the public space in a functional way, enhance the appearance.

An interesting example is the realization of Cuadra to the Port of Numana (AN): a project of landscape that is not only creating a new urban space, but use the same harmonic and functional terms. The studied composition includes a series of corten steel elements that decorate the quay of the port and at the same time integrate harmoniously with the surrounding open space: benches, litter bins, bollards and flower pot holders made of corten.

A realization that makes the beauty into the starting point for a larger project to rethink the port area in terms of efficiency: it means to live the city thinking about a space that persists over time, respecting the environmental rhythms.

Here is the project: “The Port of Numana: flower boxes made from Cuadra’s Corten steel … throw the anchor!”

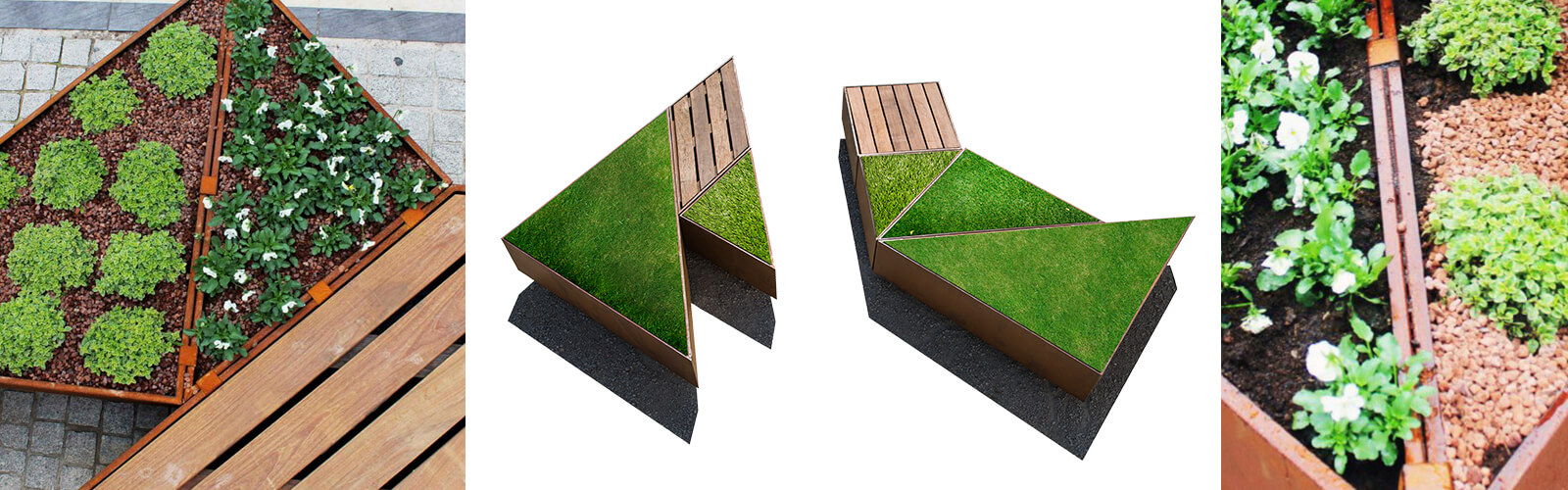

Another relevant example is the project carried through the streets of Riccione: here Cuadra, in collaboration with the architects Angela Magionami and Paola Tassetti, proposed a project based on a strong piece of his collection “Landscape Furniture”: the Tangreen, a modular system assembled and which allows the composition of endless “islands” from a single square module (2x2m) that can be decomposed and assembled in different configurations.

A versatile design, which can mutate and become continuously with the change in rules of shadows, light and that well lends itself to represent the style and the rhythm of the city of Ravenna, in an innovative way in terms of composition and social.

Read more: “With Cuadra the streets of Riccione play at tangram”

- Outdoor area – private spaces: terraces and gardens, metal flower pot holders and containers: research and experimentation of Corten steel is also increasingly encroaching in the production of functional objects for outdoor furnishing of private spaces. Here are some examples:

- Landscape modeling: one of the areas in which the (patin-able) corten steel manages to best express its potentiality is that of the creation of profiles and surfaces that allow you to model the green spaces in a practical and functional way. The borders of corten steel, in fact, encompass and contain the ground allowing you to create flowerbeds, drops and small scarps. Here are some examples:

- Facade coatings: in this case the characteristic that makes the Corten metal so interesting is undoubtedly its “chromatic potentiality”. Since it depends on climate and atmospheric factors, in fact, color is never equal to itself, and this ensures uniqueness and unrepeatability to every single realization.